|

|

High-energy UV photons allow for improved precision and performance |

|

|

UV lasers have traditionally been exceptionally expensive and large |

|

|

A new generation of small, more affordable UV lasers are increasingly accessible |

|

|

Allows for advancements in semiconductor inspection, microscopy, and disinfection |

Many laser optics applications are shifting towards using shorter UV wavelengths because it allows for improved resolution and very small and precise feature generation with minimal heating to surrounding areas. Until recently, the high cost and bulky size of continuous wave (CW) UV laser sources have traditionally prevented them from being used in many situations, especially in university research. Now, a new wave of compact, cost-effective UV lasers has broken down this barrier, resulting in an expansion of UV applications ranging from micromachining, to UV Raman spectroscopy, to disinfection for the inactivation of pathogens.

UV lasers can achieve higher spatial resolutions than infrared or visible lasers because focused laser spot size is proportional to wavelength. This allows them to be used in precise defect inspection in the semiconductor industry or in micromachining. When processing many materials, UV lasers can directly break atomic bonds rather than vaporizing or melting material, resulting in reduced peripheral heating. The high energies of UV wavelengths are ideal for exciting fluorescence in biomolecules including proteins, which is useful in a wide range of biomedical applications. Additionally, UV lasers can be used in highly-effective disinfection systems because they can sanitize surfaces by delivering high-power UVC radiation (wavelengths between 200 - 280 nm) more efficiently than UVC lamps or LEDs.1

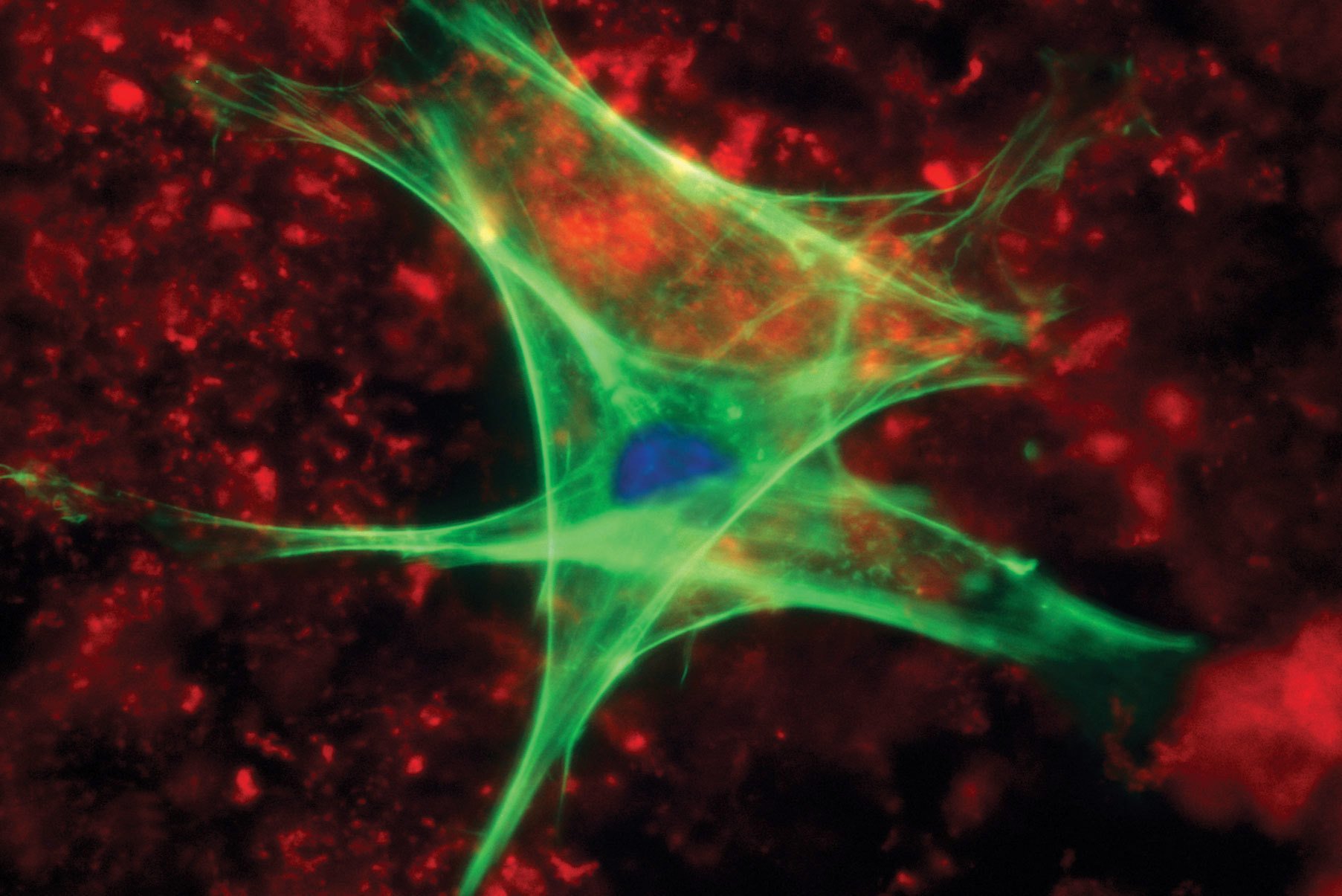

Figure 1: UV lasers are highly beneficial in a wide range of applications including fluorescence microscopy biomedical systems (left) and disinfecting surfaces to eliminate potential pathogens (right).1

Continuous-wave (CW) UV lasers have traditionally functioned by using ionized argon gas as the gain medium or frequency quadrupling near-infrared neodymium lasers. Frequency quadrupled systems require two external resonant cavities to double the frequency of the initial beam once, then repeat this process in an additional cavity.2 These systems are complex and both them and argon ion lasers are at least as large as two shoeboxes, which prevents them from being used in portable devices.

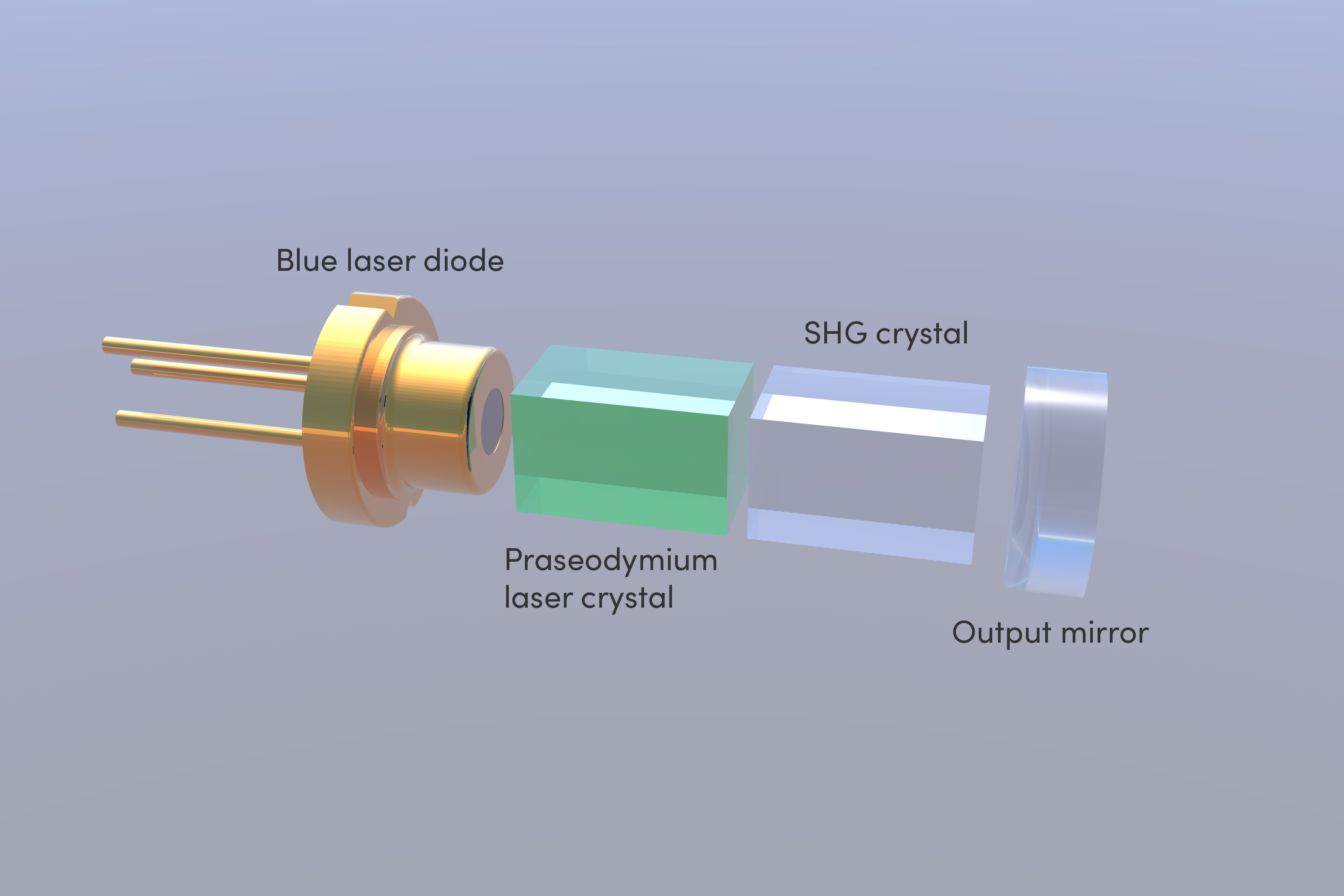

Advances in UV laser technology have resulted in smaller, less expensive devices. New, praseodymium-doped yttrium lithium fluoride (YLF) lasers developed by UVC Photonics produce a 261nm laser beam through frequency doubling rather than frequency quadrupling (Figure 2).2 This greatly reduces system complexity and the number of components required. These lasers operate similarly to laser diodes and do not require complicated electronics for locking resonance cavities or stabilizing temperatures.

Figure 2: Compact UV lasers from UVC Photonics consist of a blue pump diode, a praseodymium crystal, another crystal for second-harmonic generation (SHG), and a cavity output mirror.2

Image courtesy of UVC Photonics.

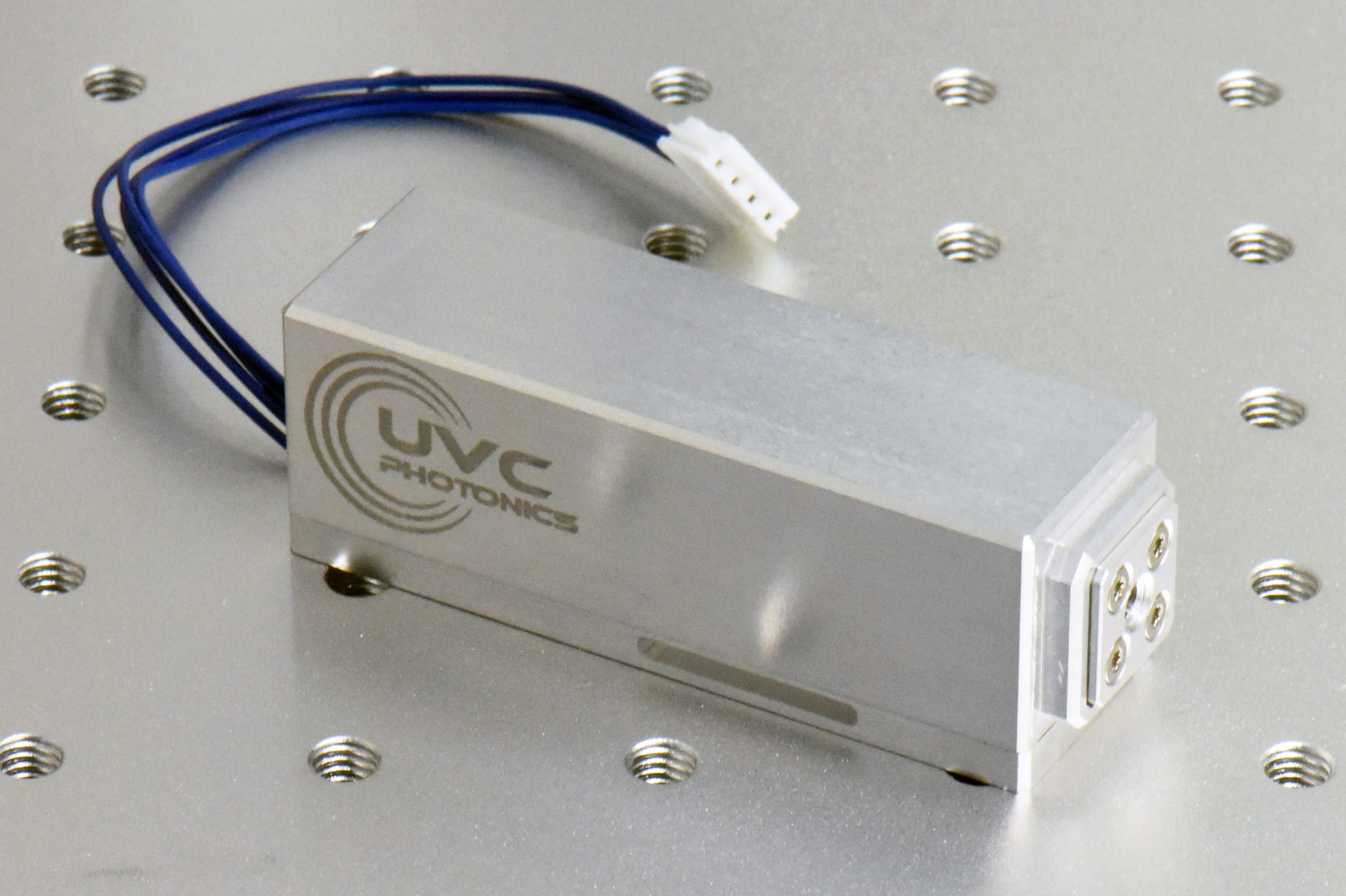

Lasers from UVC Photonics achieve >10mW of CW power at 261nm, consume less than 5W of power to operate, and are only 22 x 24 x 71mm in size.1 These properties make them ideal for portable or handheld systems, as well as university labs and industrial applications where other UV laser sources are cost-prohibitive. Argon ion lasers typically consume 10's of kW of power and produce 10’s of W of power, while frequency quadrupled UV lasers can produce up to 500mW and greater. While the older technologies can achieve higher powers, their significantly greater size and cost makes them less attractive options for certain applications. The narrow linewidth and CW functionality of these diode modules also makes them well-suited for UV ultraviolet Raman spectroscopy. More information can be found at UVC Photonics’ website.

Edmund Optics® designs and manufactures a wide range of laser optics components including those tailored for UV wavelengths. Tight surface tolerances and high laser damage thresholds allow our UV laser optics to meet the demanding needs of UV laser systems. Many optical components designed for use at 266nm (the fourth harmonic of Nd:YAG lasers) also work well at 261nm. Custom coatings and component geometries can also be tailored for your specific application.

Nd:YAG Laser Line Mirrors

Concave Laser Line Mirrors

IBS Laser Line Mirrors

Precision Ultraviolet Mirrors

Precision Spherical Ultraviolet (UV) Mirrors

Laser Line λ/20 High Tolerance Right Angle Mirrors

Laser Grade Plano-Convex (PCX) Lenses

Laser Grade Laser Line Cylinder Lenses

Hard Coated OD 4.0 5nm Bandpass Filters

λ/20 High Power Laser Line Windows

λ/10 Laser Line Coated Windows

Vega™ Laser Line Beam Expanders

Why is the laser technology utilized by UVC Photonics not more widespread?

Why is the laser technology utilized by UVC Photonics not more widespread?

Are some applications moving to wavelengths shorter than 261nm?

Are some applications moving to wavelengths shorter than 261nm?

Yes, certain high-precision laboratory applications are moving to extreme ultraviolet (EUV) wavelengths from 10-100 nm, although this is not yet widely used in industry. Learn more about this trend here.

Do optical components used with UV lasers degrade over time?

Do optical components used with UV lasers degrade over time?

Yes, the high energy of UV laser radiation degrades optical coatings and substrates over time, essentially making UV laser optics consumable components.

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2024, Edmund Optics Singapore Pte. Ltd, 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act