|

|

Some amount of light transmits through conventional dielectric mirrors |

|

|

Unwanted transmitted light introduces noise and makes laser systems less safe |

|

|

The opaque substrate of Schwarz Mirrors absorbs this unwanted light |

|

|

An engineered fused silica substrate maintains key properties of fused silica |

To prevent unwanted light transmission in laser systems, beam dumps are often placed behind every dielectric mirror. Though highly-reflective, a small amount of light always leaks through dielectric mirror coatings. This unwanted transmission can pass directly through the mirror substrate or create ghost reflections within it, decreasing laser system performance and even creating laser safety issues.

Edmund Optics' new Schwarz Mirrors can significantly reduce the need for beam dumps behind components. These mirrors are novel optical components that use opaque, engineered fused silica substrates that reduce light propagation through the mirror by several orders of magnitude while maintaining >98% of the mirror's reflective properties. The substrate itself appears black, (the word schwarz being German for black), while the beneficial properties of fused silica are maintained. Using a Schwarz Mirror can minimize the size of optical systems and improving safety by eliminating stray laser light.

While the majority of incident laser light is reflected by dielectric mirror coatings designed for those wavelengths, some amount of light will always transmit through the coating into the substrate. Fused silica and other common mirror substrates may allow this light to transfer out of the back of the mirror or create a ghost reflection, introducing stray light into the system. Wavelengths outside of the reflection band of the mirror may also pass through the mirror and further contribute to system noise, reducing system performance.

Schwarz Mirrors are constructed from an engineered fused silica that maintains the high laser-induced damage threshold (LIDT) and low thermal expansion of fused silica while also blocking unwanted light transmission (Figure 1). They feature a typical thermal expansion coefficient of 0.55x10-6/K, are opaque, and essentially function as neutral density filters.

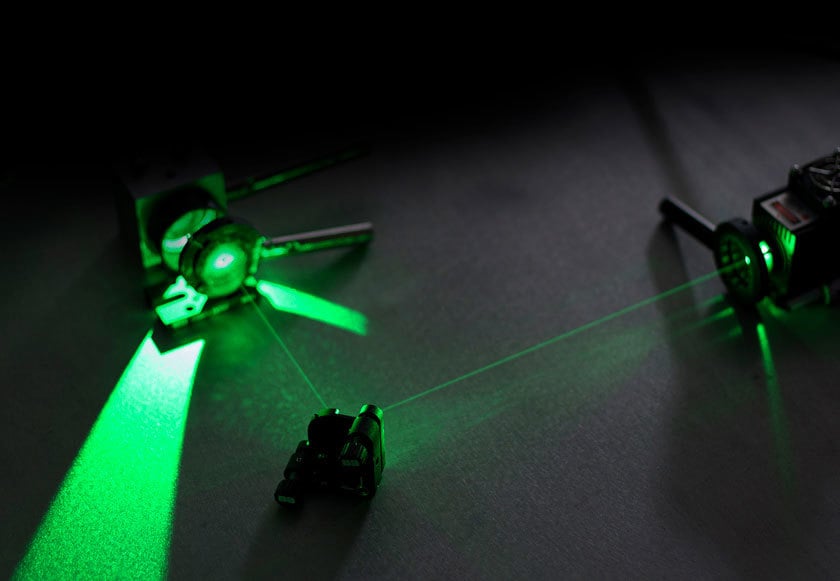

Figure 2 demonstrates the superior light blocking of a Schwarz Mirror's engineered fused silica substrate. This eliminates the need for beam dumps to be placed behind mirrors, which reduces the total system cost, weight, and size.

In order to evaluate the performance of Schwarz mirrors, a 25 mm diameter, 5 mm thick blank of black, engineered fused silica was cut and polished on one side. Transmission through the material was measured using a 532 nm diode-pumped solid-state (DPSS) continuous-wave laser with 500 mW output power and a silicon-based photodiode capable of measuring as low as 500 nW with a 10 nW resolution. No signal was detected, implying transmission of 7.

This blank was thinned and polished to 4 mm, 3 mm, and finally 2 mm without any recordable transmission to further understand the material’s ability to attenuate visible light. Using a lock-in amplifier capable of recording OD up to 9, the 2 mm sample still yielded no transmission for the visible range.

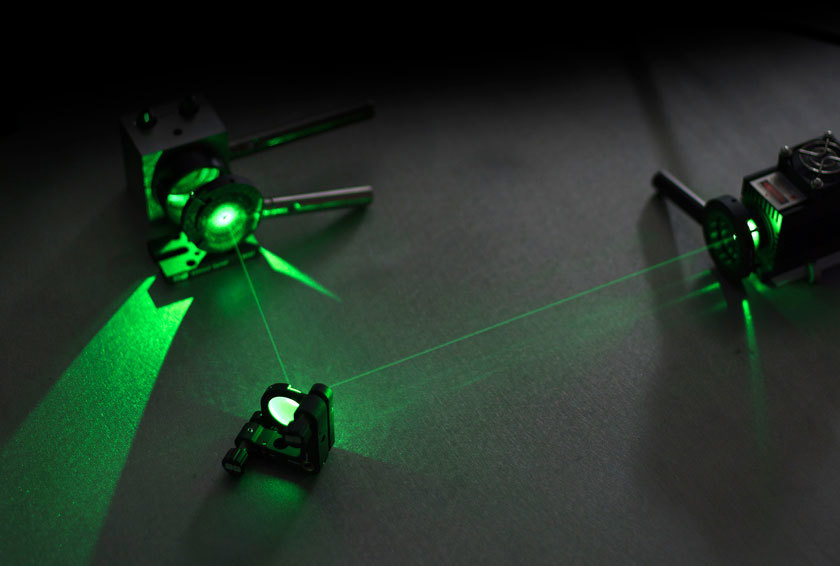

Next, the same laser and photodiode were used to compare a Schwarz Mirror and a conventional dielectric mirror with a fused silica substrate. Both mirrors had a diameter of 25 mm, a thickness of 5 mm, and the same highly-reflective dielectric coating designed for 532 nm. The laser was attenuated to 137 mW and directed onto the mirrors at a 45° as shown in Figure 2. The photodiode recorded measurements both in front of and behind the mirrors to determine reflection and transmission. Figures 3 and 4 combine data from two different Schwarz Mirror samples and two conventional fused silica mirror samples, all of which were measured five times each.

The reflected intensity was measured at 12.7 mm (near) and 304.8 mm (far) from each optic over a timeframe of five minutes. On average, these Schwarz Mirrors reflected 118.2 mW of the incident light at the extended distance, achieving 98.7% of the reflection performance of the conventional fused silica mirrors (119.6 mW). In most systems, Schwarz Mirrors could replace conventional fused silica mirrors without noticeable change in reflective performance.

The transmission was measured 304.8 mm behind the optics, on-axis with the incident beam. The conventional fused silica samples transmitted >84 µW of light while the Schwarz Mirrors had no measurable transmission with this source, again transmitting below the photodiode’s threshold of 500 nW.

Do the engineered fused silica substrates of Schwarz Mirrors make them more expensive than conventional fused silica mirrors?

Do the engineered fused silica substrates of Schwarz Mirrors make them more expensive than conventional fused silica mirrors?

Can Edmund Optics® manufacture custom Schwarz mirrors at different sizes and wavelength ranges?

Can Edmund Optics® manufacture custom Schwarz mirrors at different sizes and wavelength ranges?

Yes, Schwarz mirrors can be custom manufactured for different sizes and coating options. It is important to keep in mind that the optical density specification will decrease as the substrates get thinner.

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2024, Edmund Optics Singapore Pte. Ltd, 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act