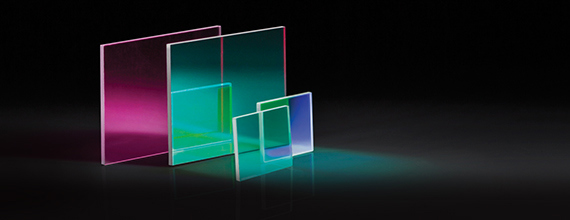

As light sources, digital sensors, and coating chamber technologies continue to improve, optical filters will naturally evolve and continue to advance. Optical filters are critical for some of the most demanding applications in automation, energy, medical imaging, security, and multi-element optical systems.

These advancements require developments on new substrates such as flexible thin film polymers and IR grade materials including silicon and germanium, or with new chemicals and compounds that yield high transmission and high blocking filters in the UV and IR spectrums. Advancements in coating chamber technology have resulted in higher precision filters yielding bandwidths of <1nm with tolerances of <1%, which truly pushes the limits of top of the line spectrophotometers. With each advancement, tolerances and specifications have been further optimized to better represent a precision substrate with improved surface quality, surface flatness, parallelism, and transmitted wavefront.

New materials, sub-nanometer specifications, deep UV to far IR spectral coverage, and various improved tolerances will continue the advancement of optics and photonics in nearly every consumer and scientific application.

Edmund Optics® continually improves our specifications and tolerances on our optical filters. The list below shows some of our newly improved optical filter capabilities.

|

|

Surface Quality of 20-10 |

|

|

Surface Flatness of λ/10 P-V |

|

|

Transmitted Wavefront of λ/20 RMS |

|

|

UV wavelengths as low as 250nm and IR wavelengths nearing 4000nm |

|

|

Filters with thicknesses as low as 200µm |

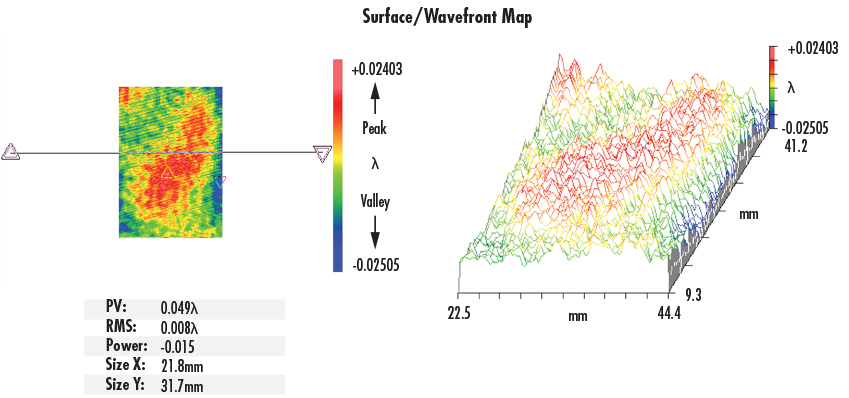

Figure 4: Surface and Wavefront Maps of a TECHSPEC® High Performance Fluorescence Dichroic Filter

Does Edmund Optics® offer filters made from thin, flexible materials?

Does Edmund Optics® offer filters made from thin, flexible materials?

What is the largest diameter filter available from Edmund Optics®?

What is the largest diameter filter available from Edmund Optics®?

The largest diameter filters that Edmund Optics® can produce are 300mm. Tolerances and uniformity become a concern on substrates this large due to sputtering and coating limitations.

What are some of the most common filter substrates?

What are some of the most common filter substrates?

Common filter substrate materials include fused silica, N-BK7, and float glasses. Recently a trend towards fluoride materials, IR crystalline materials like silicon and germanium, and polymers and plastics has emerged.

How do I select the right filter for my application?

How do I select the right filter for my application?

The first step is to determine what type of filter is required for the application. The basic types of filters are shortpass, longpass, bandpass, dichroic, notch, and neutral density. Each type of filter has unique characteristics that lend better to one application or another. The second step is to determine what wavelengths are required, as filters are defined by what part of the spectrum they pass or do not pass. For instance, an UV Cut-Off (or Longpass) filter is designed to pass both the visible and IR portions of the spectrum, but block (or "cut") the UV portions of the spectrum.

What happens when an optical filter is tilted?

What happens when an optical filter is tilted?

What types of filters can Edmund Optics® manufacture?

What types of filters can Edmund Optics® manufacture?

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2024, Edmund Optics Singapore Pte. Ltd, 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act