A Guide to (Not Over) Specifying Losses in Laser Optics

The value of properly specifying losses in laser optics is self-evident. Less evident is the point at which tighter specifications can become too much of a good thing. Overspecifying losses will not further improve your system’s performance or reliability, but it could cost you additional money and/or time.

Optical losses within laser systems are associated with scatter, absorption, transmission, and reflectivity of individual components and are all wavelength dependent. These all can contribute to total system loss and affect the survivability and longevity of the employed optical components, commonly expressed in terms of laser-induced damage threshold (LIDT) values.

Few laser systems require specifications for all these criteria, so a better understanding of when each matters can allow for a more targeted and cost-effective optimization of your laser system. Finding the right balance begins with identifying the optical losses that are critical to meeting your system’s key performance parameters and only specifying your requirements around those.

A closer look at the individual sources of optical loss in laser systems - scatter, absorption, transmission, and reflectivity - will clarify how they relate to each other and when it makes sense to specify them separately (Equation 1).

Scatter

Losses due to scatter are associated with an optic’s surface roughness, quality, and figure. Scatter reduces the overall efficiency of laser systems and can lead to premature failures of laser components and/or safety hazards in certain cases (e.g. intracavity use and system alignment).

Note that scatter tends to be greater at shorter wavelengths so controlling this source of optical loss is particularly important in UV laser systems.

Specification of forward, back, and total scatter depends, in part, on the function of the optic. Scatter measurements are made using scatterometers, instruments that employ laser sources and integrating spheres. Because scatter is wavelength dependent, measurements are only applicable when using a laser that operates at the same wavelength as the test laser and with careful consideration of the beam qualities/requirements for both lasers and the test conditions.

Absorption

Losses from absorption reduce the optimal laser output and can adversely affect a laser’s reliability and lifetime. As the incident laser radiation makes contact with a laser optic, a portion of the radiation is absorbed and is converted into heat. If enough thermal energy accumulates in the optic, it can alter its shape or refractive index (known as thermal lensing). This can reduce the emerging beam quality or adversely impact the cavity alignment. If not properly evaluated, the thermal effects of absorption can accelerate degradation of the optic and potentially lead to component, and consequently, system failure.

Figure 1: Image of laser-induced component failure, which can be initiated by thermal buildup from absorption

While this underscores the link between absorption and LIDT, the measurement and specification of these two quantities serve different purposes and should be kept separate. Absorption is a source and measure of optical loss, whereas LIDT quantifies the level of photonic energy an optic can withstand before failure.

There are several methods commonly employed for evaluating the thermal effects of absorption in optical components including laser calorimetry, as described in ISO 11551, and photo-thermal common-path interferometry (PCI), sometimes referred to as a phase-sensitive pump-probe technique. In the PCI method, the periodic local heating of the test optic by the pump beam results in the perturbed portion of the probe beam, which is phase-shifted from the refractive index change, coinciding with the pump beam. The perturbed and unperturbed portions of the probe beam interfere, which gives this method high measurement sensitivity and the ability to look at surface and bulk absorption.

Transmission

Specifying losses related to optical transmission is important when qualifying the performance of components that must transmit light with high efficiency and reliability. Transmission measurements are typically made using spectrophotometers, which use broadband light sources for operation over a wide wavelength range (Figure 2). For improved measurement accuracy and signal-to-noise ratios, it is suggested to use laser sources that more closely match the end application.

Figure 2: Spectrophotometers are often utilized to measure the transmission of optical components

The transmissive properties of a given optic at the target wavelength, angle of incidence, and input polarization are affected by both the spectral performance of deposited thin-film coatings and the internal transmittance of the substrate. A coating’s performance is also impacted by the quality of the polished surface on which it is deposited. The internal transmissive properties of the substrate require careful consideration with respect to the intended application and are commonly expressed in units of a transmission percentage per unit length.

While an optic’s transmission characteristics may influence its LIDT, it is important to distinguish these specifications. Determining LIDT is often more critical and the only specification necessary.

For transmissive optics, it is generally preferable to specify and measure transmission instead of the reflectivity of the separate surfaces. Specifying only surface reflectivity neglects the other sources of loss (see Equation 1). However, in some cases, the approximation of just specifying surface reflectivity is an acceptable cost/performance trade-off as it is easier to specify and verify.

Reflectivity

High-reflectivity mirrors and coatings are essential to the operation of any laser system, especially those designed for beam steering or optimized throughput. These systems commonly require high reflectivities above 99.9%.

In laser systems where 99.5% or less reflectivity is acceptable, the common measurement practice is the use of spectrophotometry to quantify how much light is transmitted through the mirror’s reflective surface. While this provides a clear metric, it does not fully account for additional losses due to scatter and/or absorption by optical surfaces and the bulk material. Therefore, specifying both transmission and reflectivity would be recommended for certain types of optics.

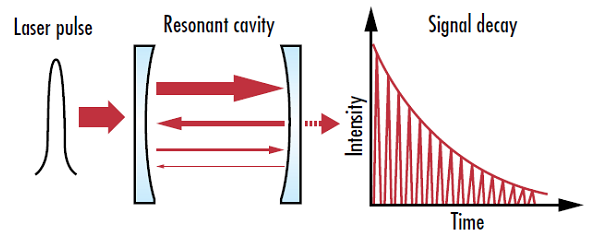

For improved measurement accuracy and better representation of real performance, laser components requiring reflectivity above 99.5% are evaluated using cavity ring down (CRD) loss meters. These determine total loss by measuring the signal decay-time in a cavity consisting of the test optic and one or two reference mirrors (Figure 3). Similar to previously mentioned specifications, it is critical to take measurements using a monochromatic light source that operates at the same wavelength at which the optic is designed. CRD accounts for losses due to transmission, absorption, and scatter, and also provides a more accurate representation of the optic’s reflectivity.

Figure 3: Cavity ring down (CRD) loss meters determine the total loss of an optical component by measuring the intensity decay rate in the meter’s resonant cavity, allowing for higher accuracy measurements than techniques that only measure transmission

Reflectivity and LIDT specifications serve different functions and should not be conflated. While mirrors and reflective coatings may have LIDT requirements to demarcate how much energy they can withstand, their reflectivity specification is a measure of optical efficiency.

Conclusion

Optical losses within a laser cavity/system are inevitable, as are the associated adverse effects on performance metrics (e.g. output power/energy and beam quality). In practical terms, however, a laser system can be built cost-effectively by identifying and specifying only the optical losses critical for system performance and the intended application.

References

International Organization for Standardization. (2008). Optics and optical instruments — Lasers and laser-related equipment — Test method for absorptance of optical laser components (ISO 11551:2003).

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023, Edmund Optics Inc., 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Act (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act