Liquid Lenses Basics

This is Section 7.1 of the Imaging Resource Guide.

Liquid Lens Basics

Liquid lenses allow imaging systems to overcome depth of field (DOF) limitations by allowing the focus to be electronically adjusted without requiring any mechanical movement. This can be a great solution for applications with varying object heights and working distances. Traditional solutions for these types of applications include motorized zoom lenses or physically repositioning the object to bring it into focus. Another way to increase the DOF in a traditional lens is to increase the f/# by reducing the aperture size of the imaging lens. However, this also reduces the resolution and amount of light that gets through the imaging system, thereby reducing acquisition rates and image quality (see System Throughput, f/#, and Numerical Aperture for more information on f/#). By integrating a liquid lens, an imaging system can change focus electronically without compromising speed or image quality, regardless of the object’s distance from the camera.

Like traditional optical lenses made from glass, liquid lenses are single optical elements but are composed of an optical liquid material that can change its shape. The focal length of a glass lens is dependent on the material it is made from and its radius of curvature. The same basic principle applies to liquid lenses, though liquid lenses are unique in that their focal length is alterable by changing the radius of curvature. This change in radius is electronically controlled and rapidly changed on the order of milliseconds. Manufacturers use electrowetting, shape-changing polymers, and acusto-optical tuning methods to control the liquid lens's radius of curvature and refractive index.

Most imaging lenses are multi-element assemblies because a single optical lens provides insufficient imaging performance. For this same reason, using a liquid lens by itself is not advised. However, integrating a liquid lens with an imaging lens in a multi-element design takes advantage of the liquid lens's speed and flexibility. Having the ability to focus both closely and to optical infinity in milliseconds makes integrating liquid lenses an ideal choice for applications that require focus at multiple distances where objects under inspection are different sizes or are at different distances away from the lens; such as barcode reading, package sorting, security, and rapid automation. Liquid lenses can be used to maximize imaging system flexibility across a wide variety of applications requiring rapid focusing.

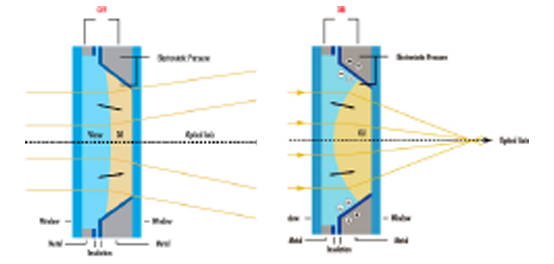

Figure 1: The focal length depends on the index of refraction of the glass and the shape of the surfaces of the lenses.

Lens Maker's Equation

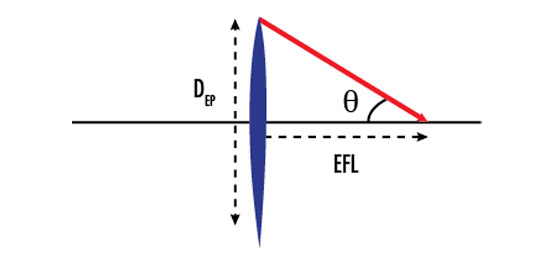

Equation 1 is the Lens Maker's Equation. This equation is used to calculate the focal length ($ \small{f} $) of a lens. The equation shows that focal length is dependent on index of refraction ($ \small{n} $), the radius of curvature of the left glass surface ($ \small{R_1} $), and the radius of curvature of the right glass surface ($ \small{R_2} $). The focal length can be shortened by increasing the index of refraction of the glass - view top image or the focal length can be shortened by changing either of the radii of curvature ($ \small{R} $) – view bottom image. Liquid lenses work by electronically controlling these properties of the lens.

Previous Section

Previous Section

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023, Edmund Optics Inc., 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Act (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act